COOKFOX and Buro Happold Design Bird and Bee Friendly Façade for Architectural Ceramics Assemblies Workshop

In August 2021, COOKFOX participated in the Architecture Ceramic Assemblies Workshop (ACAW) representing the culmination of nine months of design, experimentation, and fabrication. The Workshop is hosted by Boston Valley Terra Cotta and provides a hands-on research and development opportunity that brings design professionals together to explore innovative design solutions for architectural terra cotta. COOKFOX teamed up with façade engineers from Buro Happold to explore ceramics as a high-performance façade component outside the typical limitations of budgets and schedules.

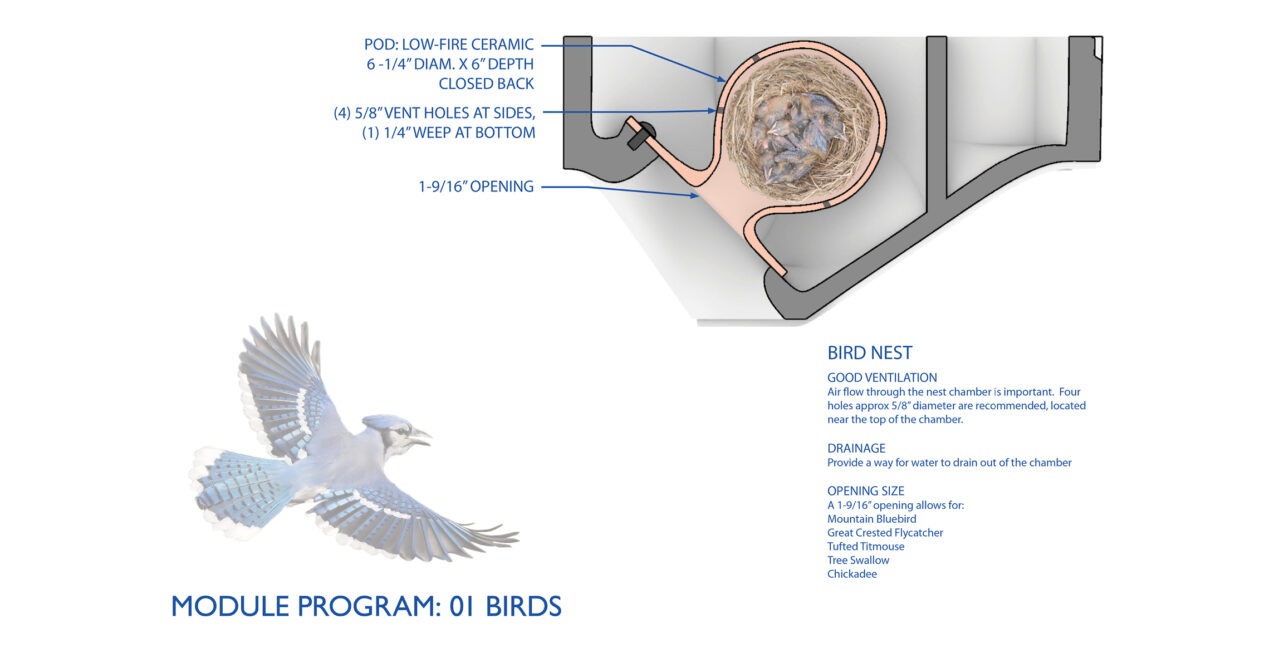

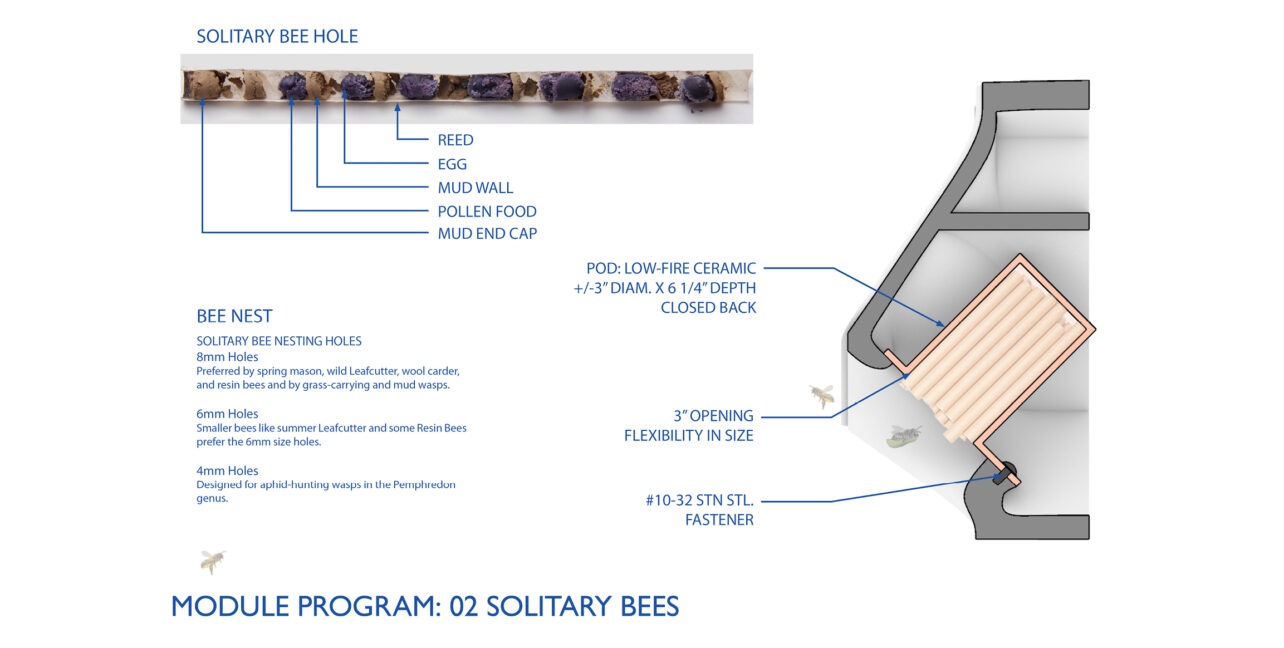

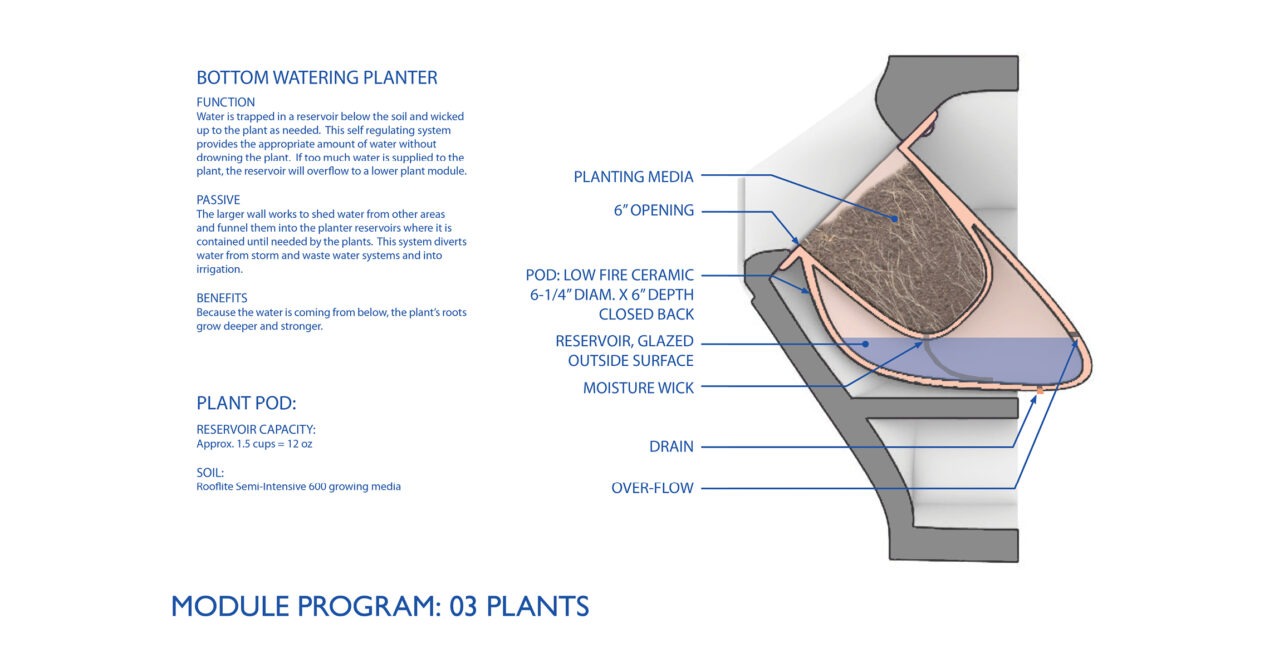

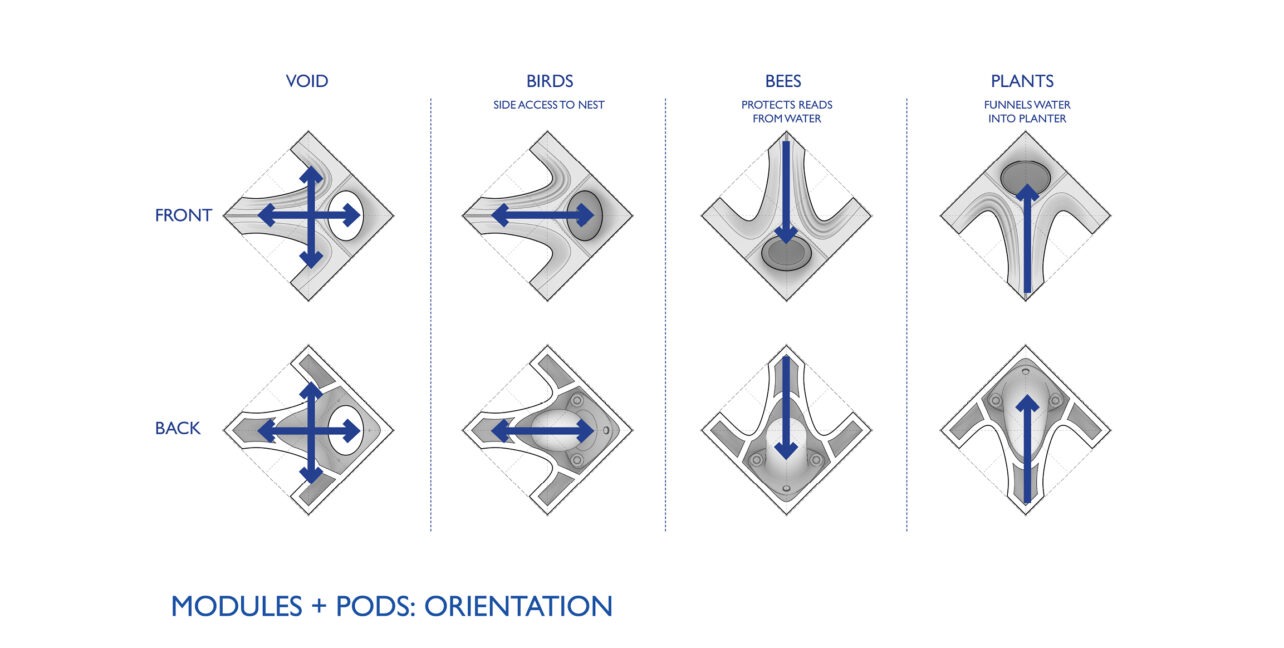

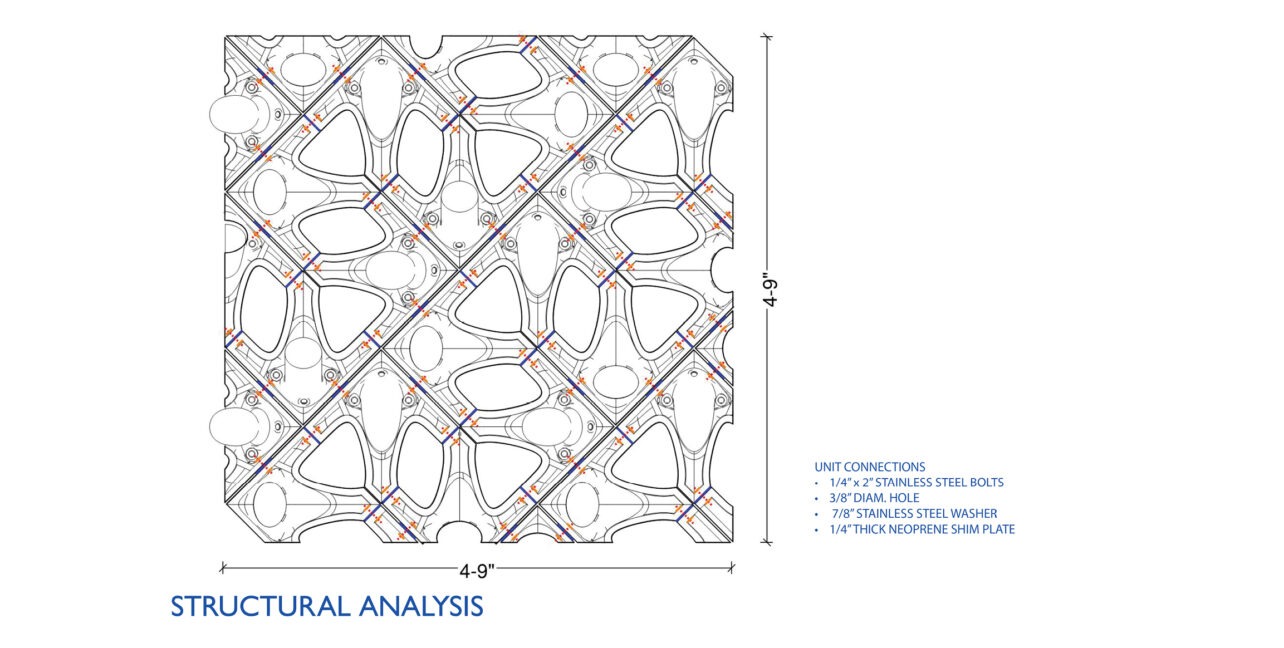

The team was inspired to push the boundaries of architectural terra cotta by creating a biophilic screen wall. A standardized stacking module filters sunlight and provides the framework for a customizable array of terra cotta units capable of accommodating the insertion of micro-habitat pods for bees, plants, and birds. The bee pod houses tubes for native solitary bees in different sizes and materials suitable for the nesting of dozens of stingless bee species native to a local ecosystem. The planter pod collects rainwater from the façade and stores excess water in its lower section for later irrigation use. A third pod creates optimal shelter and habitat for native birds. The façade supports and educates about the diverse native ecosystems that thrive in our urban environments.

The larger base modules into which the micro-habitat pots are inserted are made with a high-fired and high-grogged ceramic designed to be either slip-cast or press-molded for large scale, economical productions. This clay body is engineered to resist freeze thaw cycles, minimize shrinkage during fabrication, and is tested for the rigors inherent in façade applications. The micro-habitat pods are a slip-cast, low-fired clay body that allows for water permeability to support each pod’s program.

During the design process, the team worked with the fabricators to develop custom glazes and pigmented clays called ‘engobe’. This incremental experimentation allowed the team to study the various properties of color, opacity, and sheens, as well as how a glaze can pool in valleys or ‘break’ over peaks and how glaze interacts with engobe. The process also considered the benefits and limitations of high-volume industrial production.

The COOKFOX and Buro Happold team started collaborating in December 2020 and met remotely throughout the winter to develop the design. The ceramic pods and modules were fabricated in Kansas City, MO and shipped to the Boston Valley factory in Buffalo, NY. In mid-August, the team met in Buffalo to assemble the full-scale mockup of the screen wall and components.

Team

COOKFOX | Spencer Lapp, AIA, Associate and Zach Grzybowski

Buro Happold | Andre Parnther, Associate and Spring Wu, LEED AP, Façade Engineer